| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Tianci Heavy Industry

Model Number : 1-200000TPY

Certification : CE,ISO9001,SGS

Place of Origin : China

MOQ : 1

Price : 30000-300000

Payment Terms : L/C,T/T

Supply Ability : 168

Delivery Time : 5-8weeks

Packaging Details : Wooden

The NPK fertilizer production line using extrusion granulation with a roller press granulator is a common process for manufacturing nitrogen-phosphorus-potassium compound fertilizers. Process Flow of NPK Fertilizer Production Line by Extrusion Granulation with Roller Press Granulator.The process mainly relies on mechanical pressure to granulate materials, without the need for high-temperature melting or excessive moisture addition.

| No. | Types of materials | Raw materials list |

| 1 | Nitrogen | Urea,Calcium nitrate,Ammonium bicarbonate,Ammonium chloride,Nitrate of soda,Ammonium sulphate nitrate,Ammonium sulphate,Ammonium nitrate,etc |

| 2 | Phosphorus | MAP(Monoammonium phosphate), DAP(diammonium phosphate),SSP(calcium superphosphate),TSP(triple superphosphate), calcium magnesium phosphate fertilizer, etc |

| 3 | Potassium | MOP(Potassium chloride),SOP(potassium sulfate),Potassium nitrate, potassium phosphate, potassium hydroxide, etc |

| No. | Processes | Machines | Function of machines |

| 1 | Dosing | Automatic dosing system | Ratio raw materials by formula |

| 2 | Crushing process | Crushing machine | Crush raw material into powder(if need) |

| 3 | Mixing and blending process | Mixer/Blender | Mix powder evenly, If need, |

| 4 | Granulation process | Feeding machine | Feed mixed powder into granulating machine evenly |

| Granulating machine | Make mixed powder into fertilizer granules | ||

| 5 | Drying process (if need) | Rotary dryer | Dry fertilizer granules to low moisture by hot |

| Hot furnace | Generate hot air to dryer | ||

| cyclone | collect dust from dryer | ||

| 6 | cooling process (if need) | Rotary cooler | cool fertilizer granules to normal |

| cyclone | collect dust from cooler | ||

| 7 | Screening process | Screening machine | screen out required size from fertilizer granules |

| 8 | Coating process (if need) | Rotary coating machine | Coat color, anti-blocking agent, micro elements etc on fertilizer granules |

| 9 | Packaging | Air compressor | Generate air source to packaging machine |

| Packaging machine | Package fertilizer granules into bags | ||

| 10 | Delivering process | Belt conveyor | Connect each machine, and deliver the powder or granules to next process |

| 11 | Controlling process | PLC controller | Control all machines |

| Item | Technical indicators | ||

| High density | Medium density | Low density | |

| Total nutrients(N+P2O5+K2O)/% | ≥40 | ≥30 | ≥25 |

| Water-soluble phosphorus to available phosphorus/% | ≥60 | ≥50 | ≥40 |

| NO-N/% | ≥1.5 | ≥1.5 | ≥1.5 |

| Moisture content/% | ≤2 | ≤2.5 | ≤5 |

| Size(1-4.75mm or 3.35-5.6mm)/% | ≥90 | ≥90 | ≥90 |

Note: the indicators above is based on chinese standard, only for reference, different country maybe different.

Q: What are the typical raw materials used in this production line?

A: The raw materials used in the Organic Fertilizer Granules Production Line include compost manure, farm waste, city garbage, and other organic materials.

Q: What is the capacity range of this production line?

A: The capacity of the Organic Fertilizer Granules Production Line ranges from 1 to 300 tons per hour.

Q: What is the maximum allowable humidity level for raw materials in this production line?

A: The maximum allowable humidity level for raw materials in the Organic Fertilizer Granules Production Line is ≤30%.

Q: Is this production line automated?

A: Yes, the Organic Fertilizer Granules Production Line is fully automatic, minimizing manual intervention and maximizing efficiency.

Q: What are the key steps involved in the production process?

A: The production process of the Organic Fertilizer Granules Production Line includes crushing, mixing, granulating, screening, and packaging.

Q: What is the shape of the granules produced by this production line?

A: The granules produced by the Organic Fertilizer Granules Production Line have a ball-type shape.

|

|

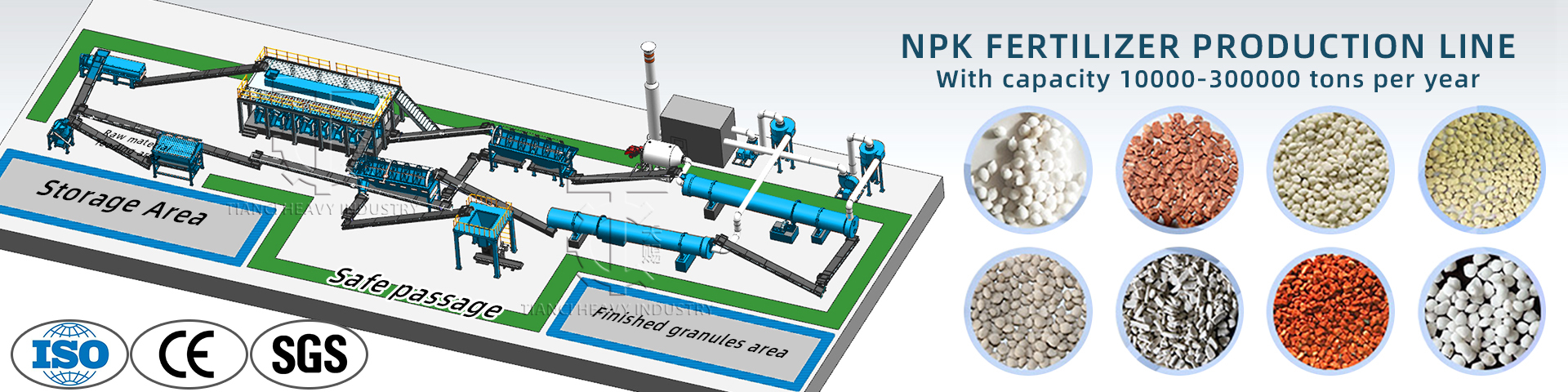

NPK Fertilizer Production Line By Extrusion Granulation With Roller Press Granulator Images |