| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : TIANCI

Model Number : pan granulator

Certification : CE,ISO9001,SGS

Place of Origin : China

Pan granulator (also as know Disc Pelletizer,or disc granlator), it is a type of fertilizer granulator that is used to produce granules from powdered materials. The disc granulation machines achieve particle aggregation through the cohesive forces of binders or water molecules, combined with the rolling motion of materials within the rotating disc.As the pan rotates, the material is agitated and forms into small round granules. The granules are then dried and screened to achieve the desired size and shape. Pan granulators are commonly used in the production of fertilizers, as well as other industries that require granulation such as pharmaceuticals and food processing.

The disc granulator machine, also called disc pelletizer, is used in various industries for making granules from different materials. Its applications include:

Fertilizer Production: It granulates different types of fertilizers, making them easier to handle and improving nutrient release for better crop yield.

Mining and Metallurgy: It agglomerates mineral concentrates, ores, and tailings, making them easier to transport and process.

Chemical Industry: It granulates chemical powders like catalysts and additives, improving their flowability and handling characteristics.

Pharmaceutical and Food Industries: It granulates pharmaceutical powders and food additives, ensuring controlled release and precise dosing.

Chemical Engineering and Research: It helps scientists and engineers study and optimize the granulation process for different materials in laboratories.

• Agricultural field: In the production line of NPK compound fertilizer with an annual output of 100,000 tons, disc granulator has become the mainstream choice due to low energy consumption and good particle uniformity;

• Environmental protection field: When municipal sludge is pelletized for treatment, the advantage of adhesion of disc pelletizer is utilized to make sludge into fuel pellets;

• Chemical industry: Calcium carbonate, magnesium carbonate and other powders are granulated to improve product fluidity and transportation safety through disc rolling molding.

• Applicable material type:

It can handle organic fertilizer, inorganic fertilizer (such as NPK compound fertilizer), chemical raw materials, metallurgical powder and other granular or powdery materials, especially suitable for the system containing viscous components (such as clay, humus) or the need to add binder (such as water, syrup, molten material).

• Raw material moisture tolerance:

Requirements for the moisture content of raw materials are relatively loose (usually allowed 5% ~ 20% humidity), and in some cases, it can directly process wet materials, reducing the pre-treatment process.

• Flexible adjustment of particle size and shape:

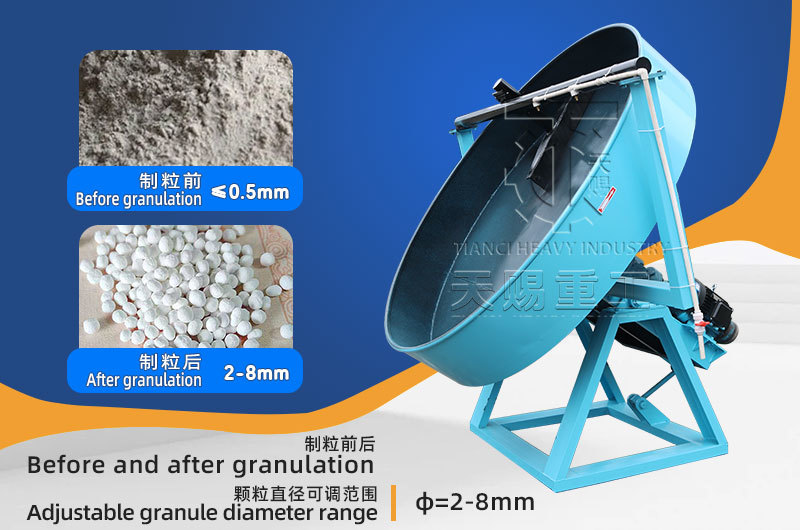

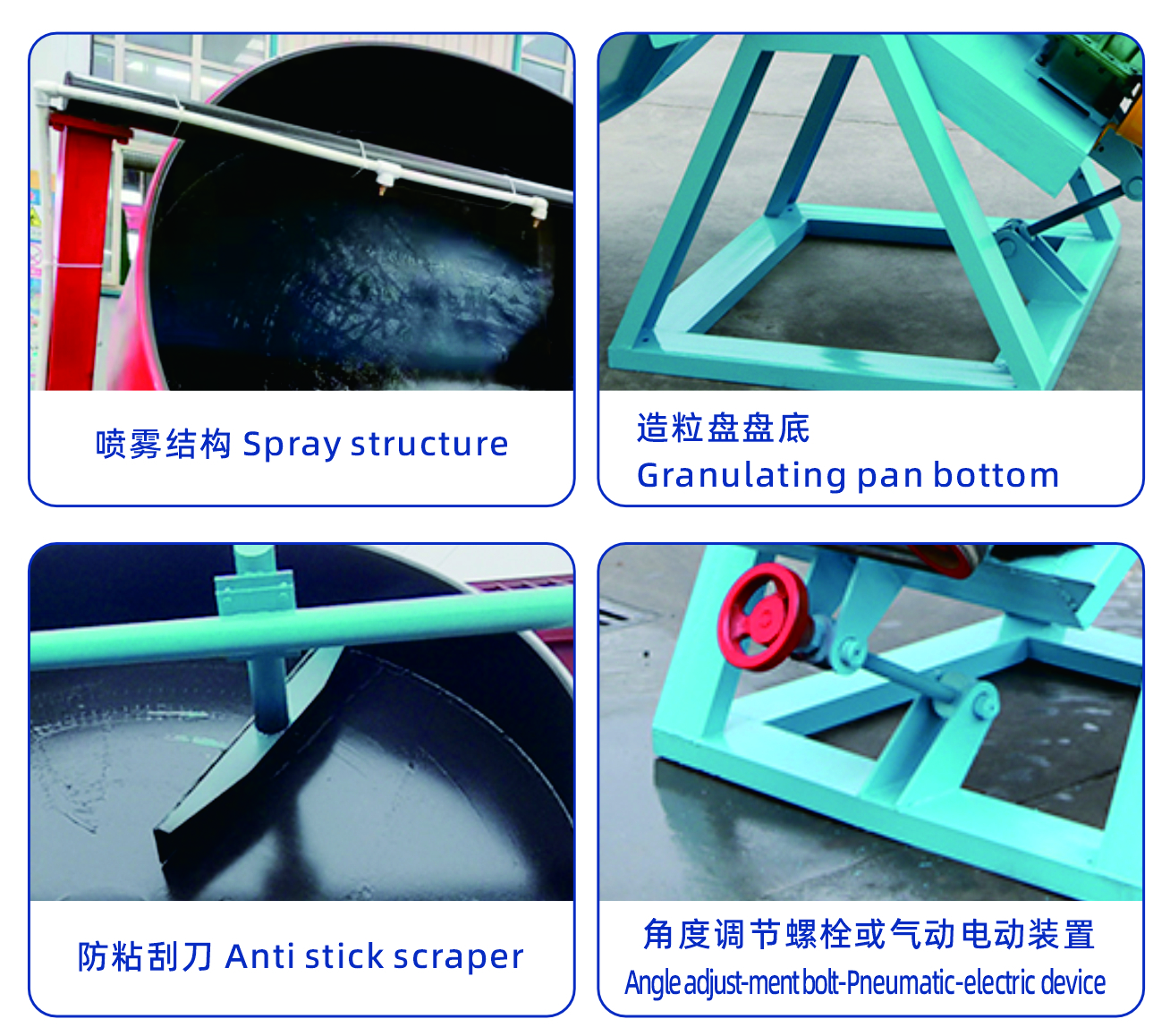

◦ By adjusting the inclination angle of the disk (usually 30°~60°), rotational speed (10~30rpm) and material residence time, particles of 2~10mm particle size can be produced, and the particles have a high degree of sphericity (close to ellipsoid) and a smooth surface.

◦ Example: the higher the inclination angle and the higher the rotational speed, the smaller the particle size; conversely, the larger the particle size.

• Adjustable particle strength:

Depending on the amount of binder and rolling compaction, the hardness of the granules can be controlled and adapted to different transportation and application scenarios (e.g., mechanized seeding requires high granule drop strength).

• Mechanical construction advantages:

Mainly consists of disc, drive device, bracket, no complex transmission parts (such as churn, mold), equipment failure rate is low, routine maintenance only need to check the bearing lubrication and disc wear.

• Easy replacement of wear parts:

The surface of the disc can be coated with wear-resistant coatings (e.g. ceramic, polyurethane), and the cost of replacement after wear and tear is much lower than that of the roll-press assembly of an extruder pelletizer.

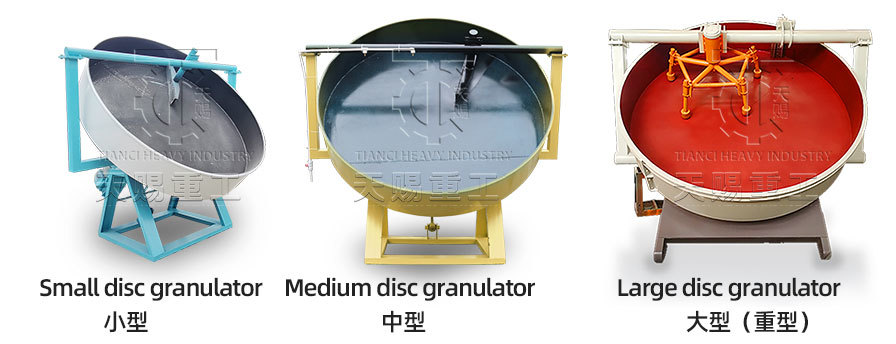

Small disc granulators are commonly used for small-scale fertilizer production or for laboratory research. They are compact and easy to operate, making them suitable for use in small spaces or by inexperienced operators.

A medium disk granulator is a type of equipment used for producing fertilizer pellets. It is similar to a small disk granulator, but with a larger size and higher production capacity. Medium disk granulators are commonly used in medium-sized fertilizer production plants.

A large disc granulator is a type of equipment used for producing fertilizer pellets on an industrial scale. It is similar to a medium or small disc granulator, but with a much larger size and higher production capacity. Large disc granulators are commonly used in large-scale fertilizer production plants.

New Organic Fertilizer Pan Granulator: A new organic fertilizer disc granulator is a type of equipment used for producing organic fertilizer pellets. It is an updated version of the traditional disc granulator and is designed specifically for producing organic fertilizer pellets.

Particle size controlFlexible and adjustable, high sphericity Good uniformity of particle size, but flattened shape Wide range of particle sizes and irregular shapes

Binder dependenceRequires little binder or moisture No binder required (dry granulation) Requires a lot of water or binder

power consumptionLow (0.5~1.5kWh / ton) Medium (2~5kWh / ton) High (3~8kWh / ton)

Suitable materialsOrganic fertilizer, compound fertilizer, clay-containing materials Inorganic fertilizer, high hardness raw materials High-moisture materials, mass production

Q: How many tons of fertilizer can a disc granulator produce per hour?

A: TIANCI disc pelletizers can produce 0.3-20 tons per hour, depending on the raw material's specific gravity and the equipment type/specification. For precise details, please consult our customer service.

Q: What are the main materials of the disc granulator?

A: The body of TIANCI disc granulator is made of carbon steel, stainless steel, etc.

Q: What is the diameter of the granules processed by the disk granulator?

A: The diameter of the finished granules can be adjusted from 2mm to 8mm (by modifying process parameters).

|

|

Pan granulator for ammonium and potash fertilizer granulation equipment on the disc granulator granulation production line Images |